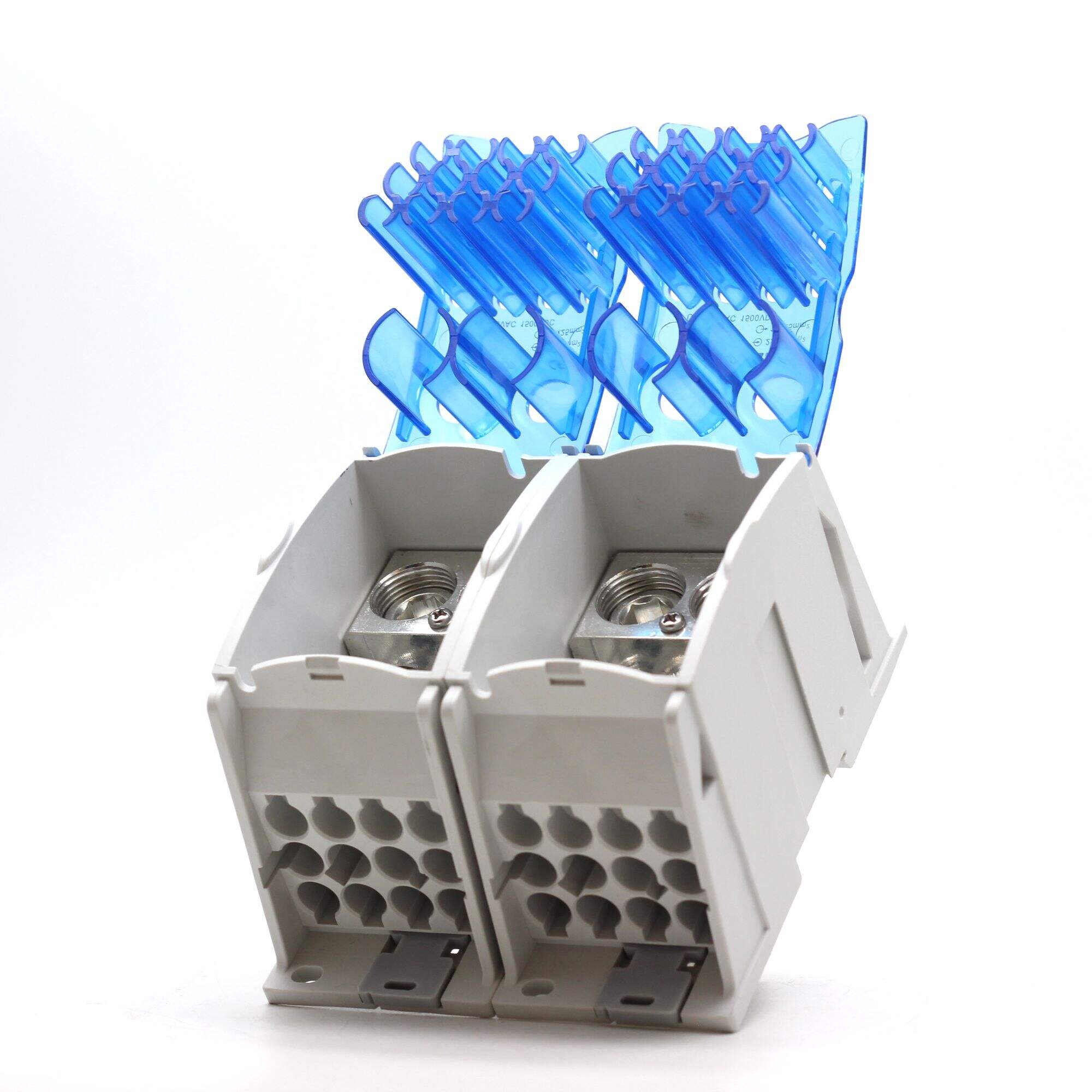

Connecting Electrical Wires Using Terminal Connectors

If you are looking to connect wires run electricity through them safely and securely, terminal connectors should be your choice. These connectors come from leading production terminal connector suppliers, comply with stringent safety requirements and offer a safe solution that is reliable and convenient for all wiring installations. This blog explains the many advantages of using terminal connectors by Feman Electric, looks at some unique examples from smart products customer installations and discusses why choosing quality options is important for safety across a range applications.

Advantages of Terminal Connectors

What sets terminal connectors apart from traditional wire nuts or crimps is that they are just so much better in way of multiple benefits. Most importantly, they are tight connections that ensure a solid permanent bond between wires and switch to minimize the risk of electrical fires or shorts. Furthermore, electrical terminals connectors are easy and quick to install; typically, just using a basic crimping instrument. Moreover, particular connectors are intended for special types of wires such as those that can be seen in an automotive or marine setting to maximize diversity in performance and protection.

Terminal Connectors Innovation

The world of terminal connectors is constantly changing as quality manufacturers add new bells and whistles to their products that suit today's market. Other connectors, for example, electrical terminal connectors are more frequently utilizing new materials or coatings to protect against corrosion of extreme heat. Some have custom shapes or designs which make it easier to install a feature and enhance its identity. Some suppliers also provide design services and manufacturing for you to make a product that is more suitable exactly what your project needs.

Safety and How to Use

Safety over everything is what distinguishes terminal connectors as a top safety article. They are made in accordance with rigorous industry standards of bodies like UL or CSA, so they can be seamlessly integrated into different types applications. Follow manufacturer instructions with the terminal connectors, ensuring you have chosen the proper size and style of connector for those specific wires (using the correct crimping tool), and that it makes a well-sealed connection.

How To Use And Repair Terminal Connectors?

Using terminal connectors are not that intricate and they only require some basic tools which are normally found in every household, as well a rudimentary amount of technical knowledge. Start out with the right connector for your wire and make sure it is clean, no defects or problems. Strip the wire insulation to bare up a section of each cable, then push it through into connectors all the way until your wires are at about that bottom. Use crimping pliers to compress the contact, making sure that the wire is fully fixed. Finally; heat up and shrink the heat-shrink tubing provided with it (using a heat gun or similar). If you do find any problems with your terminal connectors then make sure to take advice from the manufacturer or supplier as they normally offer a full service and support for all products including addressing concerns.

Quality and Application

You can find different terminal connector quality based on the producer or seller. But here we have to fight for the same kind of manufacturer who does a professional production in those terminals by forming connectors that will, more than meet all standards required from industrial applications and be also safe, reliable and effective. Some suppliers for instance, might even proceed a step further by taking additional quality testing or certifications such as the ISO 9001; which is to reinforce their commitment. They are used for various applications, including automotive terminals and marine and other industrial electrical connection systems (in boat masts/arms etc.) They are especially essential in applications that require a safe and trusted connection over the long term, such as wire harnesses, circuit boards or electrical panels. Customers can have the peace of mind in knowing that their electrical connections are safe, reliable and high efficiency by using premium terminal connectors from trusted suppliers.

In short, high-security and convenient manner which has no flaws at all terminal connector for production given by professional you can opt. Boasting an array of high-end qualities, the materials these connectors are made from and how they have been engineered make them a must-have item for your next project that requires dependable connections you can trust. If you follow the manufacturer's instructions and choose the right connector for what it is to be connected, then effectively maintained your electrical connections are reliable if not guarded.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR